Material selection

Products

Products containing eligible plastic parts, whose combined weight exceeds 200 g shall contain on average >25% post-consumer recycled plastic or >30% post-industrial/post-consumer recycled plastics.

Products containing leather elements, such as remote controls and headphones, are developed in partnership with Muirhead – who manufacture environmentally low impact leather for prestigious global brands in the premium and luxury goods sectors. Muirhead’s long-term commitment to responsible and sustainable manufacturing has been driven by a series of forward-thinking initiatives such as their Thermal Energy and Water Treatment & Recycling plants, enabling Muirhead to manufacture the world’s lowest carbon intensity leather, measured at just 1.1kg of CO2 per hide.

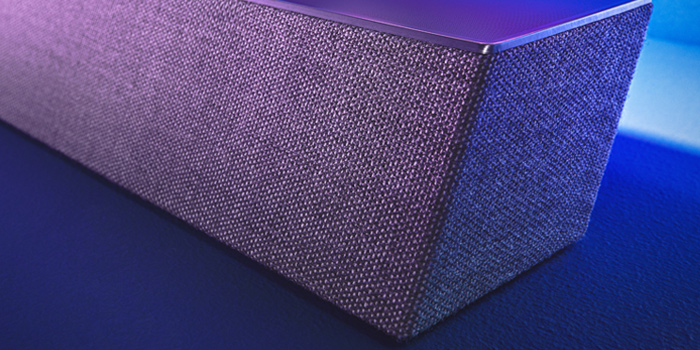

TP Vision’s collaboration with Kvadrat is focused on the company’s specialist wool and polyester products. Kvadrat has its own production site in the UK for wool weaving with the woollen textile supplied to TP Vision earning an EU Ecolabel certification. Wool is a natural, regenerative resource with a long lifespan, it is also naturally stain-resistant and flame-retardant, so chemical treatment is not necessary. Waste fibers from the production process are also, wherever possible, gathered and recycled.

Polyester textiles are durable and easy to maintain. Furthermore, the yarns are hypoallergenic as they are synthetic and not animal-based. Polyester with 100% composition is thereby easy to recycle. Hypoallergenic yarns provide a cleaner indoor environment for people who suffer from allergies and they have a shorter production processes than natural fibres.

Packaging

We do not use EPS or other polymeric foam materials for screen size 43” and smaller. We replaced EPS by airbags made of polyethylene and paper pulp, which are more environmentally friendly to recycle.

For paper and cardboard, we use > 90% recycled content or 100% from certified renewable sources.