Latest developments

Our commitment to the environment

There’s no simple way to be able to instantly turn a commercial organization into a sustainable one. Rather the route to sustainability is long, complex and requires the consistent commitment of all parts of a business – with each needing to contribute to the planning and implementation of an overall strategy. TP Vision has already implemented a wide range of activities over the past two years to support the TPV Groups overall sustainability objective and one of the first projects that has been undertaken is the organization’s research and subsequent response to the environmental impact of product packaging.

TV packaging

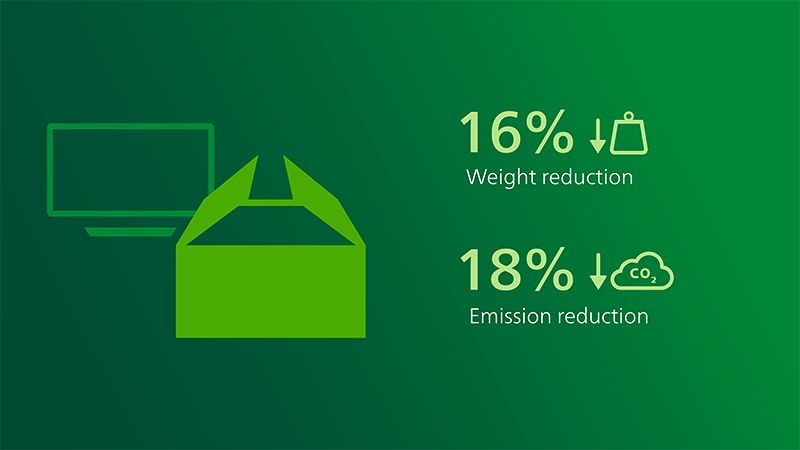

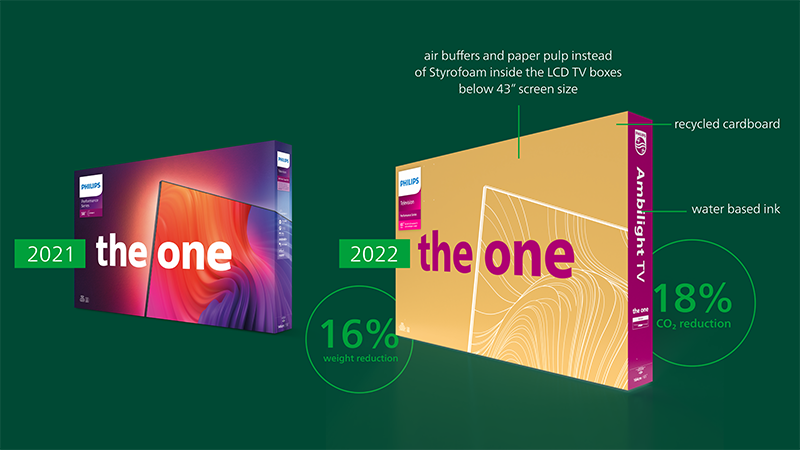

TP Vision began the research into the overall carbon footprint of TV packaging back in 2021.This analysis focused on the entire life cycle of the packaging, from raw material extraction to final disposal. The first changes as a result of that analysis were introduced in 2022, with the company no longer producing full colour packaging, changing to brown boxes with white outlines in the shape of the product – with water-based inks plus limited coloured elements to distinguish each series globally. In addition, LCD TVS below 43” screen size were introduced plus air buffers and paper pulp packaging instead of Styrofoam. The changes have already had a significant impact.

When compared to the company’s 2021 TV sets, the 2022 TV packaging has enjoyed a weight reduction of 16% and offers a CO2 reduction of 18% which – together with the optimisation of other materials and processes – has led to an overall operational reduction of 3,202 (3.202.000 KG) tons of CO2-eq. A reduction equivalent to the CO2 generated by 6,068 flights from Amsterdam to New York. In 2023 TP Vision’s consumer TVs packaging reached the next goal by using FSC-certified carton. This ensures that the packaging material is only sourced from responsibly managed forests.

TV set materials

Similar environmental impact assessment projects have been undertaken concerning the materials used to manufacture the TV sets. Since 2021, the Philips TV EU range – including entry, mid-range and high-end models – has used post-consumer recycled (PCR) plastics in the manufacture of the sets’ back covers, with the ratio of PCR plastics increasing each year. Currently – depending on the specific model – the back covers are manufactured with a PCR plastics content of between 30% & 50%, with TP Vision committing to continually increasing the amount of PCR plastic in future products.

TV remote control

One of the new TV remote control features, to be implemented in all European markets, is a dedicated ‘green button’. Identified by a green leaf, the long of press of the green button key will lead the user directly to the Eco menu and to recommendations of how to achieve lower power consumption. In addition to offering a better and more personal user experience, the green button will also lead to a more conscious and easy way of watching television while saving some energy. For all of our remote controls we use 85% post-consumer recycled plastics per 2024.

Headphone packaging

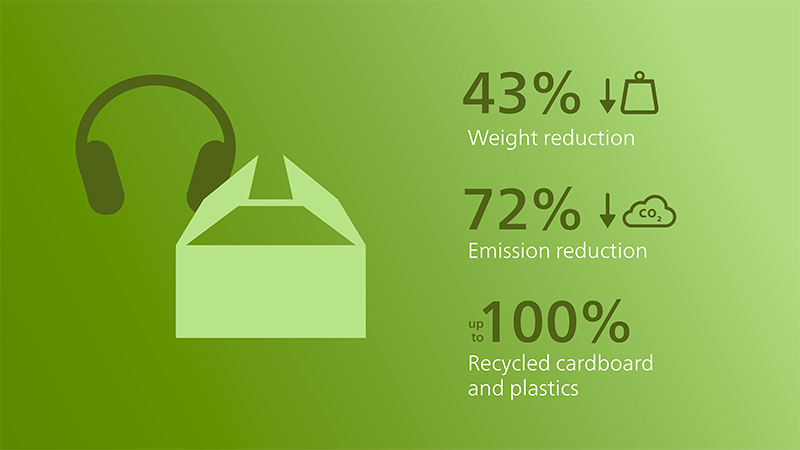

The company introduced a number of changes in 2022 including the phasing out of virgin plastics, adding 90/100% recycled cardboard – with inner trays switched to paper pulp/cartons – and reducing the overall volume of packaging to downsize boxes by approximately 40%. Full colour boxes were also changed to brown boxes with colour print sleeves.

In the specific case of two 2021 headphones models – the TAA7306 and TAA6606 – in comparison with their 2022 successors – the TAA7507 and TAA7607 – the project resulted in a weight reduction of 43% and a CO2-reduction of 72%.

Headphone with self-charging solar cells

TP Vision continually evaluates ways to manufacture new and more sustainable products. As part of that process the company has announced a new partnership with Swedish tech company Exeger in 2023. Exeger has developed its patented Powerfoyle™ solar technology specifically for consumer electronics products and the two companies have co-developed a new headphone model – the A6219 – featuring self-charging solar cells which can recharge in all types of light and then offer a fully charged run time of up to 80 hours. Furthermore, the product is made with 35% post-consumer recycled plastic.

General

All companies selling TVs, among other products, in the European Union will need to ensure that those appliances can be repaired for up to ten years to help reduce electrical waste. The ‘right to repair’, as it is sometimes called, is part of a broader effort to cut the environmental footprint of manufactured goods by making them more durable and energy efficient. In support of this initiative, TP Vision launched an online spare parts web shop in March 2021.

TP Vision has also centralized multiple TV and audio warehousing into the one facility in Gorzow, Poland. All stock of products for European markets is now distributed from the one central location that is conveniently placed for the European motorway network, greatly increasing the speed and efficiency of deliveries.

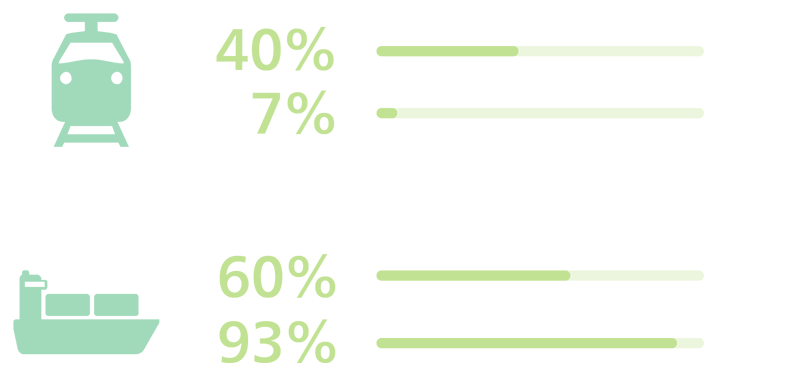

The company has also invested in advance logistics planning to ensure that shipments from the TP Vision factories in China are made by sea rather than rail. The result is that in 2023, shipments by sea rose to 93% from 60% in 2022, with product movements by train falling from 40% to just 7% in the same period.